ABB LLT100 Laser Level Transmitter

The ABB LLT100 is specifically made for industrial applications and harsh environments.

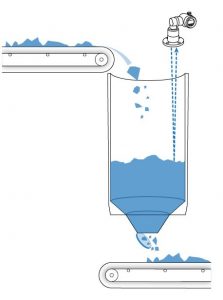

It provides continuous, non-contact level measurement capabilities for process automation and inventory management in industries such as mining, aggregates, oil & gas, chemicals, food & beverages, power, pulp & paper, pharma, and water & waste water.

ABB brings laser level transmitters to the next level of non-contact measurements by packaging laser ranging technology with the required features for industrial applications.

Using a pulsed laser to perform time of flight measurement, the ABB LLT100 provides accurate distance measurements while being powered from the 4-20mA loop.

Available in aluminium or stainless steel body, it comes with a variety of process interfaces. It can meet the demands of hazardous area locations, high pressure and high temperature applications.

Available in aluminium or stainless steel body, it comes with a variety of process interfaces. It can meet the demands of hazardous area locations, high pressure and high temperature applications.

ABB LLT100 Overview

- Low cost of ownership

- No maintenance or calibration necessary

- Versatile level transmitter

- Reliable

- Precise measurement of any solid or liquid surface

- Dust and fog penetration capabilities

- Explosion proof class 1 / division 1 (zone 1)

- Convenient

- Fast and flexible installation

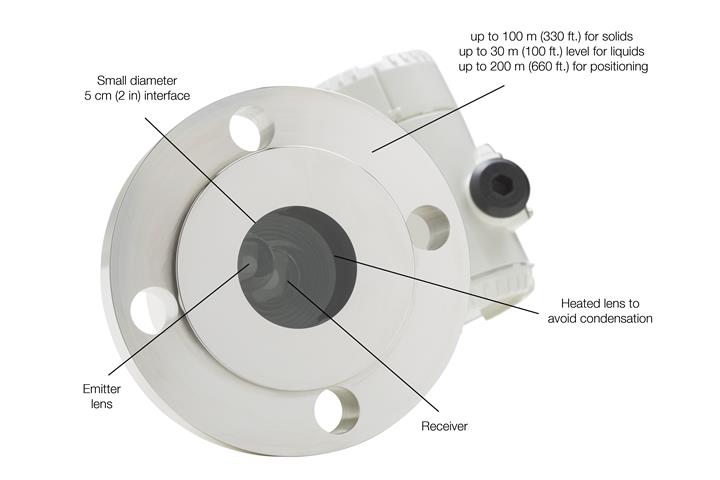

- Heated window prevents condensation on window (requires 4 wire power)

- Easy setup function

- 2 wire powered and HART communication

- Fast delivery

- Less than 2 weeks from order to reception

ABB LLT100 Accessories

- Dust tube

- Avoids dirt or splashing liquids on the window

- Cooling tube

- Increases max. process temperature to 280°C/535°F

- Integral through-the-glass (TTG) user interface

- Configuration directly on the unit

- Rotating bracket

- Ideal for aiming the LLT100 laser beam

- Swivel flange

- Provides precise aiming of the LLT100 laser beam. Especially useful in liquid applications

- Laser pointer tool

- Used to provide a visual reference when aligning LLT100

ABB LLT100 Introduction Video

ABB LLT100 Measurement

- Range

- Liquids: 0.5 to 30m (2 to 100ft)

- Solids: 0.5 to 100m (2 to 330ft)

- Positioning applications: 0.5 to 200m (2 to 660ft)

- Resolution

- 5mm (0.2in)

- Typical accuracy

- ±11mm (0.4in)

- Measuring beam

- Laser wave length: 905nm, eye safe, Class 1

- Laser beam divergence

- 0.35°

ABB LLT100 Environmental conditions

- Operating temperature

- –40° to +60°C (–40 to +140°F), up to 280°C (535°F) with cooling tube

- –40° to +60°C (–40 to +140°F), up to 280°C (535°F) with cooling tube

- Storage temperature

- –40 to +85°C (-40 to +185°F)

- Survival temperature

- –40°C to +80°C (–40°F to +175°F)

- Process pressure

- Base model: –1 to +2 bar (29 psi)

- Hygienic model: –1 to +1 bar (15 psi)

- Pressure-rated model: –1 to +49.6 bar (719 psi), depending on flange

Output

- Analogue

- 4 to 20 mA, NAMUR compliant

- 4 to 20 mA, NAMUR compliant

- Digital

- HART 7 (multi-variable output)

- Communication

- Local HMI, EDD/DTM, handheld

Power supply

- Powered from the loop

- 4 to 20 mA, 16 to 42 V DC

- Heated lens option

- 24 VDC (3W)

ABB LLT100 Mechanical

ABB LLT100 Mechanical

- Enclosure material

- Powder coated aluminium (standard), 316L stainless steel (option)

- Dimensions

- Universal – flat flange W 247 x H 215 x D 165 mm (9.7 x 8.5 x 6.5 in.)

- Class 150 – raised flange W 240 x H 242 x D 154 mm (9.5 x 9.5 x 6.1 in.)

- Class 300 – raised flange W 247 x H 242 x D 165 mm (9.7 x 9.5 x 6.5 in.)

- DIN PN 16 – raised flange W 247 x H 242 x D 165 mm (9.7 in x 9.5 x 6.5 in.)

- DIN PN 40 – raised flange W 247 x H 242 mm x D 165 (9.7 x 9.5 x 6.5 in.)

- Hygienic flange W 223 x H 215 x D 137 mm (8.8 x 8.5 x 5.4 in.)

- Weight of standard model

- Aluminium enclosure with universal aluminium flange: 3.7 kg (8.2 lb)

- 316L SST enclosure with universal stainless steel flange: 8.6 kg (19.0 lb)

- Weight of pressure rated model

- Aluminium enclosure: 6.7 to 7.2 kg (14.8 to 15.9 lb), depending on flange

- 316L SST enclosure: 10.0 to 10.5 kg (22.1 to 23.2 lb), depending on flange

- Weight of hygienic model

- Aluminium enclosure: 5.8 kg (12.8 lb)

- 316L SST enclosure: 9.1 kg (20.1 lb)

- Protection class

- IP66 / IP67/ Nema 4 (SS version 4X)

- Process fitting

- Flange (ASME 2”, DN50)

- Hygienic fitting / tri-clamp 4 in. (ISO2852)

- Wetted parts

- Aluminium, cemented borosilicate window (base model)

- 316L SST, cemented borosilicate window (base model, hygienic model)

- 316L SST, fused borosilicate window (high pressure models)

ABB LLT100 Operation

- Display

- Integrated 128×64 pixels LCD display with TTG (Through-The-Glass) interface

- Software features

- Volume computation, damping, filtering, thresholds/alarms, user-defined display (with HMI)

- Approvals

- CE, ATEX, IECEx, FM, 3A

ABB LLT100 PDF Downloads

Contact

- 01706 216667

- 01706 216681

- instruments@whgood.co.uk